2000 - Current

2002: Incorporating NATCOM burner technology, Industrial Combustion releases an upgraded version of their LN burner lines to include single-digit NOx capability.

2007: R&D develops the V-series burners. The V/series is a competitively priced line of commercial-industrial burners including high turndown and low NOx performance.

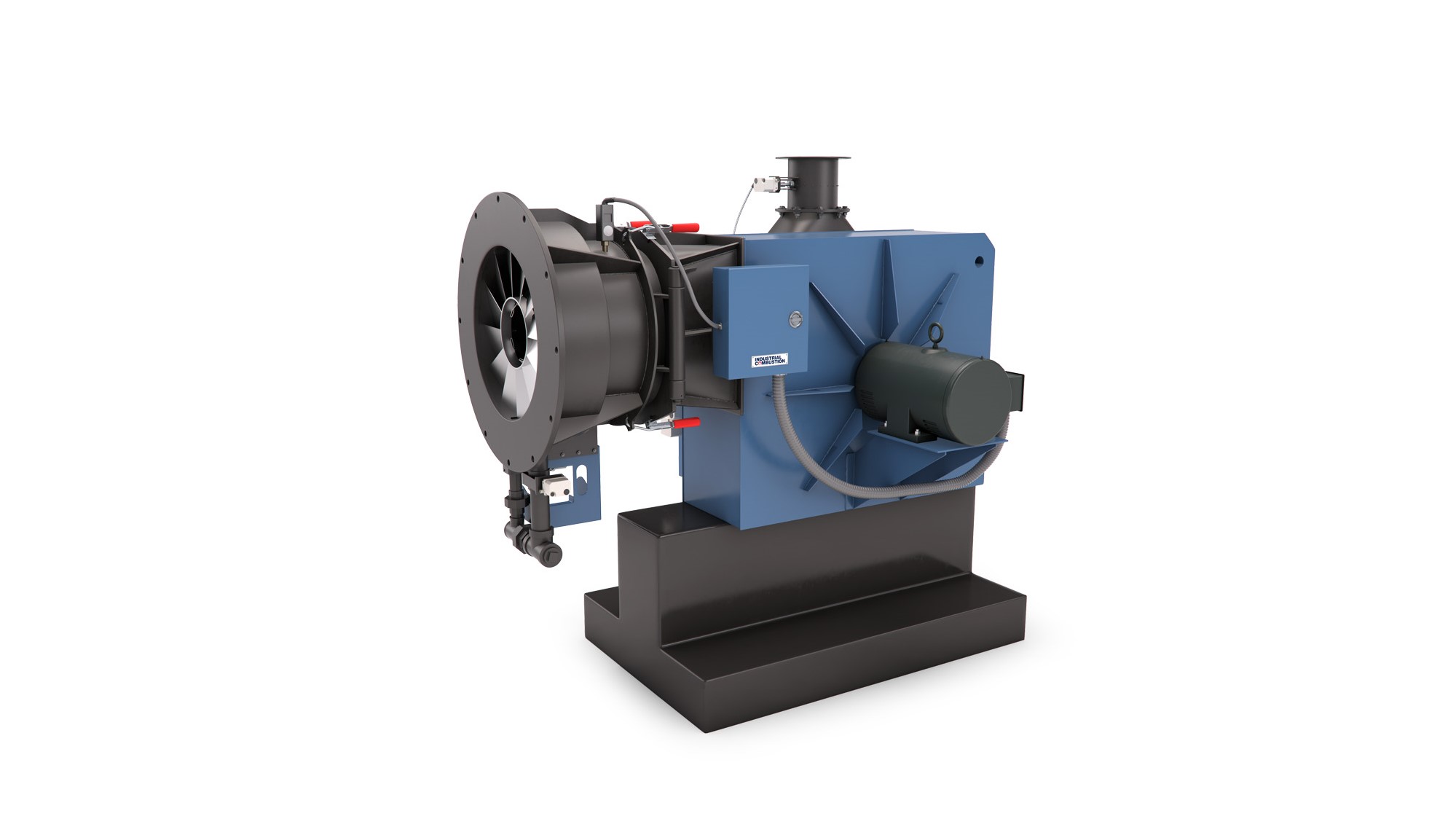

2008: Two major lines of burners are targeted for release this year: The E/series burner line ranging from 200 through 1,500 BHP - features not only include high turndown on gas and light oil, as well as low NOx capability, but reduced motor horsepower requirements by up to 50% over the D and S1 product lines.

Another product with a staged release beginning this year is the XL burner line targeting larger sized firetube boilers.This product is targeted for low and ultra-low NOx performance up to 92+ MMBH input.

2021: The SBR-30 was officially launch. This revolutionary burner is capable of less than 30 ppm NOx emissions without FGR. SBR-30 models range from 400-1300 BHP